UDMmc

2, 4 Axis Drive Module, 80V, up to 20/40A

EtherCAT ® Drive Module, Unique, Compact, Cost Effective

-

Universal dual/quad motor Drive Modules for EtherCAT networks

12Vdc to 80Vdc, up to 20A continuous and 40A peak current

-

Outstanding servo performance

20kHz sampling rate

Advanced algorithms including ServoBoostTM(optional)

Gantry MIMO Control

Dual feedback

Digital control for easy setup and diagnostics

Supporting any of the following type of motors by software settings only:

2, 3 phase AC Servo / DC brushless with sinusoidal commutation, DC Brush, voice coils, Closed and open loop step motors

-

Feedback

4 digital incremental encoders

4 absolute encoders (optional)

-

Digital I/O (all can be used as general purpose I/O)

Inputs: 4 Registration MARK (High Speed Position Capture)

Outputs: 1 PEG (Position Event Generator), 4 motor brake (24V, 0.5A)

-

Safe Torque Off (optional)

-

A wide range of current selection

Two axis versions, current rating per drive:

5A / 10A (cont. / Peak), 10A / 20A, 20A / 40A

Four axis versions, current rating per drive:

All four axes with 2.5A / 5A (cont. / Peak), 5A / 10A, 10A / 20A, 20A / 40A

Two axes with 5A / 10A & two axes with 10A / 20A

Two axes with 5A / 10A & two axes with 20A / 40A

Two axes with 10A / 20A & two axes with 20A / 40A

-

Compact footprint: 152 x 138 x 48 mm3

|

|

The UDMMC is a line of compact EtherCAT modules of two and four universal drives with rating of 12 to 80Vdc and 2.5A (5A peak) to 20A (40A peak) per drive. Each drive is programmable to control a 3 & 2 phase servo motor, a DC brush motor, a voice coil motor and a 2 & 3 phase step motor.

The UDMMC addresses the needs of demanding multi-axis motion applications with limited space, such as waferhandling robots, wire bonders, die bonders, electronics packaging, small manipulators, and table-top motion stages. With the optional powerful ServoBoostTM algorithm (ordered with the controller), demanding positioning systems can achieve ultimate performance levels, such as speeds of meters per seconds and Nanometers of jitter, minimal settling time, and uncompromising system robustness with minimal sensitivity to disturbances and changes. Optional Safe Torque Off (STO) cuts the power to the motor without removal of the power source for applications that are required to comply with SIL-3 and PLe safety levels. The UDMMC is a slave that runs under any ACS’ EtherCAT masters. The 4-axis UDMMC can be ordered with mixed current specifications. See Ordering Options.

A comprehensive set of software support tools are provided for configuration, setup, tuning and diagnostics.

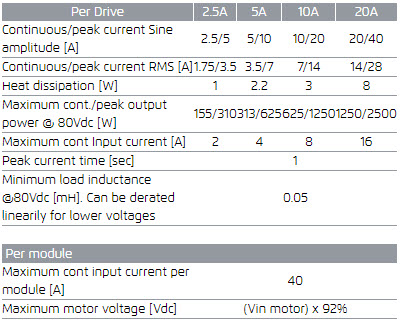

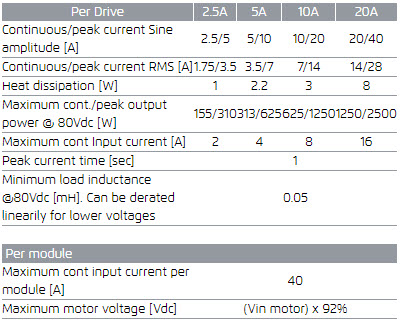

Specification

Drives

Type: digital current control with field oriented control and space vector modulation.

Current ripple frequency: 40 kHz.

Current loop sampling rate: 20 kHz.

Programmable Current loop bandwidth: up to 4kHz, will vary with tuning & load parameters.

Commutation type: sinusoidal. Initiation with and without hall sensors.

Switching method: advanced unipolar PWM.

Protection: Over & under voltage, Phase to phase and phase to ground short, Over current, Over temperature.

Power Supplies The drive must be supplied by two power sources

A motor supply and a 24Vdc control & logic supply.

During emergency conditions there is no need to remove the 24Vdc control supply.

Motor Supply Range: 12Vdc to 80Vdc

Current rating should be calculated based on actual load.

External shunt power resistor, activated at 83V, should be added in parallel to motor supply, which must not exceed 85V under any operating conditions.

Control Supply Range: 24Vdc ± 20%

Maximum input power:

Without motor brakes:19W (0.8A @ 24Vdc)

With 4 motor brakes: 67W (2.8A @ 24Vdc)

Motor Type

Two- and three-phase permanent magnet synchronous (DC brushless/AC servo), DC brush, Voice coil, Two- and three-phase stepper (micro-stepping open or closed loop), Five-phase stepper*. (*Consult ACS)

Feedback

Types: incremental digital encoders, optional:

absolute encoders

Incremental Digital Encoder: Four, one per axis.

A&B,I and Clk/Dir, Type: Differential RS-422 or single-ended

Max. rate: RS-422 - 50M quad counts/sec,

Single-ended: 2M quad counts/sec.

Protection: Encoder error, not connected

Absolute encoders (optional): Up to four.

EnDat 2.1(Digital)/2.2, Panasonic, Smart-Abs, BiSS-A/B/C, SSI.

Hall inputs:

Four, a set of three per axis. Type: single-ended, 5V, source, opto-isolated

Input current: <7mA

5V feedback supply

Feedback devices are fed by a 5V±5% supply.

Total current provided by the internal supply:

0.5A. If more current is needed, an external supply should be used, using the dedicated connector

Digital I/O

Axis’ Limit inputs: Eight, Two per axis.

Type: Single-ended, 5/24V±20%,opto isolated, sink/source. 4-14mA per input

Unused limit inputs can be used as general purpose inputs

STO: Two inputs. Current per input <50mA

All drives are disabled within 50mS to 200mS

Registration MARK (High Speed Position Capture) Inputs: Four, 24V±20%, opto-isolated, two terminals. Can be configured as ‘sink’ or ‘source’. Input current 4-14mA. Can be used as general purpose inputs.

Motor Brake Outputs: Four, opto-isolated, source, 24V±20%, 0.5A. Can be used as general purpose outputs.

Position Event Generator (PEG): One, RS422.

Can be used as general purpose output. Pulse width 26nSec to 1.75mSec. Maximum rate: 10MHz

Drive Protection

- Over & under Voltage

- Short circuit: Phase-to-phase, Short to ground

- Over current

- Over temperature

Environment

Operation: 0 to + 50°C

Storage and transportation: -25 to +60°C

Humidity (operating range): 5% to 90%

non-condensing

Communication

Two EtherCAT ports, In and Out, RJ45 connector

Dimensions

152x138x48 mm3

Weight

1,000 [gram]

Accessories

UDMmc-ACC1: Mating connectors kit for drives, encoders and I/Os

STO-ACC1: Cable for STO with mating connector

|